The manufacturing industry faces unique challenges: complex product data, shorter market cycles, and rising quality standards. The missing connection between product data and related assets, combined with scattered files and time-consuming searches, slows manufacturing companies down.

Digital Asset Management (DAM) is the solution to these challenges. A professional DAM system organises, manages, and distributes all digital content across the manufacturing industry in a central and efficient way. It connects seamlessly with existing PIM systems to establish a direct link to relevant product information.

Table of Contents

Key challenges in manufacturing

The manufacturing sector faces specific hurdles that require a modern solution for managing digital assets:

- Time-to-market pressure

- Data volume and complexity

- Compliance and security

- Multi-channel challenges

Time-to-market pressure

Competition in manufacturing is fierce. New products need to reach the market faster than ever.

Lengthy coordination processes between marketing, development, and sales cost valuable time. When different teams work with outdated or incorrect product assets, launches get delayed even further, and companies lose market share to faster competitors.

Data volume and complexity

Modern manufacturers produce enormous amounts of digital assets every day. Product photos, technical drawings, 3D models, animations, manuals, and marketing materials pile up quickly.

These assets often exist in multiple versions, formats, and languages. Without centralised management, it is easy to lose track.

Compliance and security

Manufacturers operate under strict compliance requirements. Technical documentation must be up to date, product information legally correct, and safety data sheets complete.

At the same time, digital assets often contain sensitive information about new products or production processes. This data must be protected from unauthorised access. A data breach could be disastrous.

Multi-channel challenges

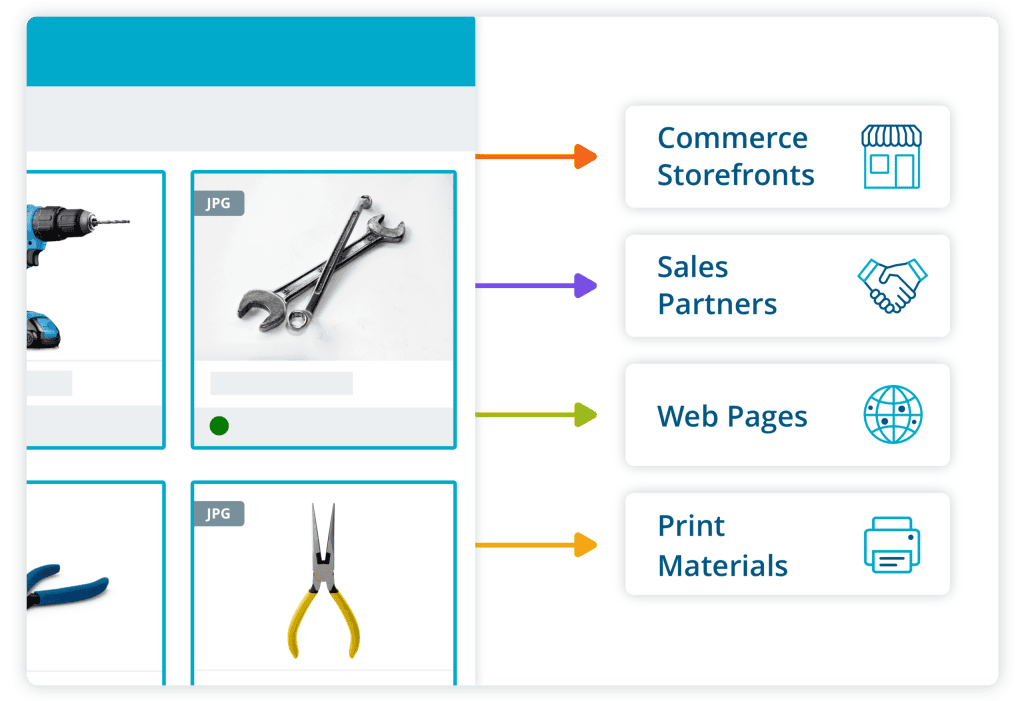

Manufacturers distribute their products through multiple channels: websites, online shops, catalogues, trade fairs, and sales partners. Each channel requires different image sizes, formats, and content.

Without centralised management, outdated product images or inconsistent descriptions are used quickly. This damages the brand and confuses potential customers.

How DAM supports the manufacturing industry

A high-end DAM solution systematically addresses these challenges and makes your processes more efficient:

- Centralised asset management

- Accelerated product launches

- Brand consistency and quality assurance

- Improved collaboration

Centralised asset management

- A single source of truth for all digital assets: with DAM, manufacturing companies can store all product images, documents, and media in one central place. Everyone works with the same, up-to-date data.

- Automated workflows for asset creation and approval: define clear processes for creating and approving new assets. The system automatically forwards content for review and notifies the right people.

- Efficient search and categorisation: find what you need in seconds thanks to smart search functions and structured categories. No more endless folder digging.

Accelerated product launches

- Streamlined content creation: optimised workflows shorten the time from product development to market launch. All teams work in parallel instead of one after another.

- Parallel approvals: marketing, technical, and sales teams can approve different assets simultaneously. The system avoids conflicts and ensures smooth collaboration.

- Automated asset distribution: once assets are approved, the system can automatically distribute them to all relevant channels, saving time and avoiding manual errors.

Brand consistency and quality assurance

- Version control and change history: every asset update is logged, and earlier versions are stored. You always know who made which changes and when, which is crucial for quality assurance and compliance.

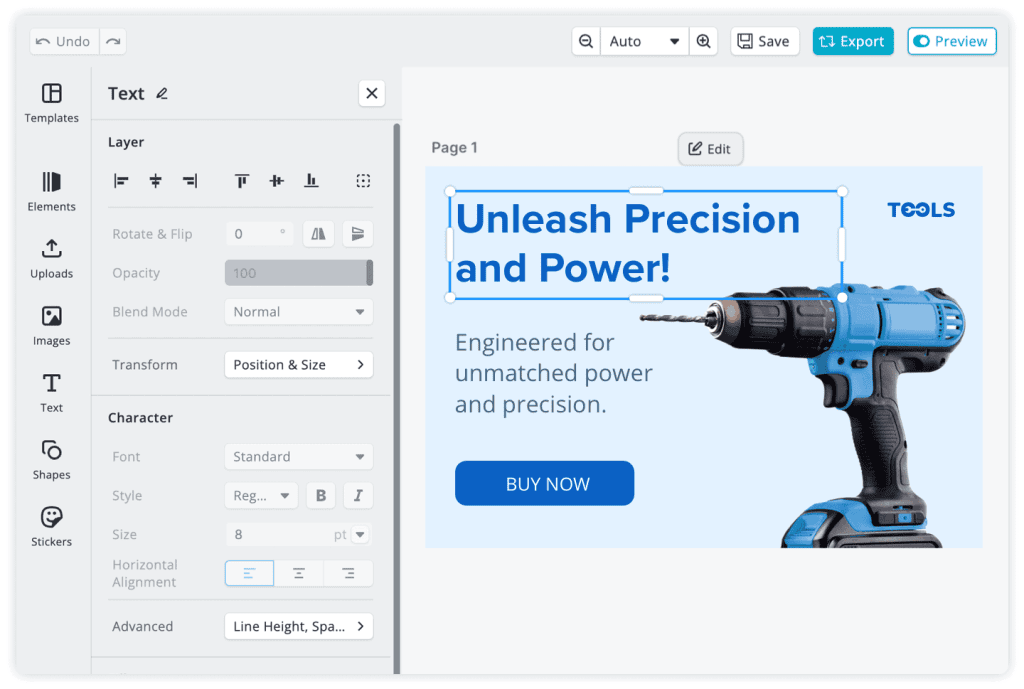

- Template-based content creation: create consistent content templates for asset types like business cards, product brochures, or price lists. This ensures all content looks professional and on-brand.

Improved collaboration

- One central platform for internal and external stakeholders: internal teams, agencies, and partners all work on the same system, with controlled access to the latest assets.

- Role-based permissions: you decide who can view, edit, or download which assets. Sensitive information stays protected.

- Real-time collaboration and feedback: teams can comment directly on assets and provide feedback instantly. Requested changes reach the right people immediately.

What to consider when choosing a DAM system for manufacturing?

Choosing the right DAM system is key to success. Here is what you should look for:

- Integration with existing systems: your DAM should connect seamlessly with PIM, ERP, PLM, or CRM.

- Scalability: your DAM must grow with your business. Look for flexible storage and user licences.

- Workflow automation: choose a system with configurable workflows. Approvals and distribution rules should be adaptable.

- Security features: make sure it includes two-factor authentication and granular permission controls.

- Metadata management: a strong system automates metadata extraction and management, simplifying search and categorisation.

- Version control: automatic versioning ensures you can always roll back to older versions.

- Support and training: choose a vendor that provides solid onboarding and reliable support. Implementing DAM is a major project.

What is the difference between MAM and DAM?

Many manufacturers wonder whether they need a DAM or a MAM system. While often used interchangeably, there is an important distinction.

Media Asset Management (MAM) focuses on managing and editing audio and video content. MAM systems are built for media and broadcasting industries, offering features for video editing, transcoding, and metadata tagging of moving images.

Digital Asset Management (DAM), however, is broader. It manages all types of digital assets: images, documents, videos, 3D models, CAD files, and more. For manufacturing, this variety is essential. DAM systems also integrate seamlessly with PIM, ERP, and CRM systems, which is crucial for product data management.

For manufacturing companies, DAM is the better choice as it covers the full range of product content and integrates smoothly into your existing system landscape.

Why a high-end DAM outperforms the DAM features of a PIM system?

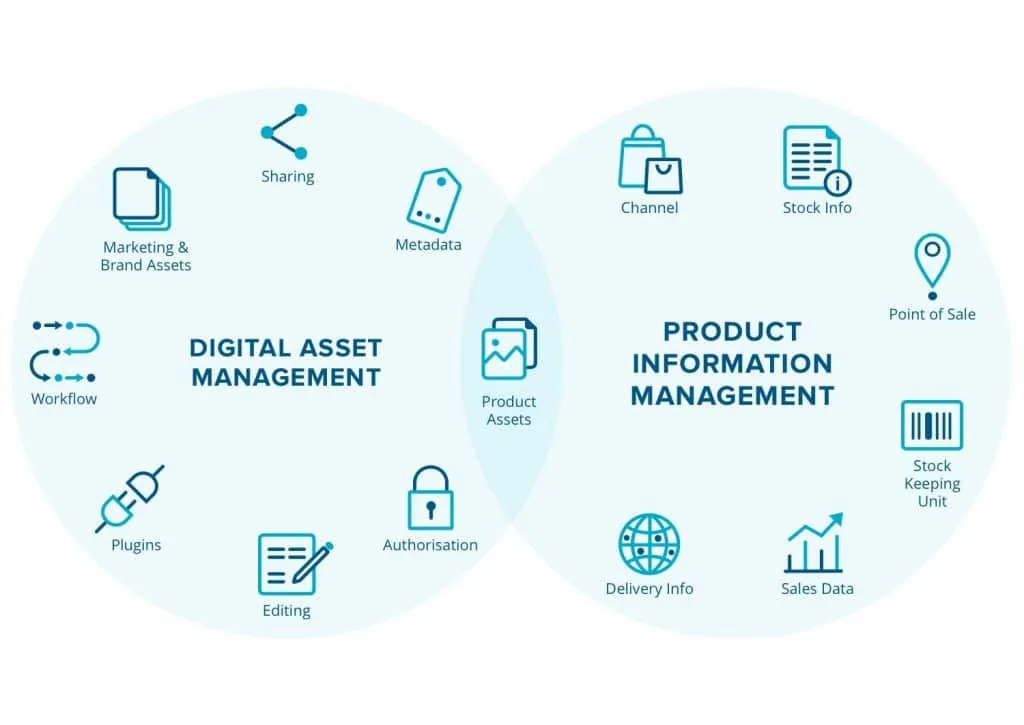

Many Product Information Management (PIM) systems include basic DAM functions, but these rarely meet the needs of professional manufacturers.

PIM systems are designed primarily for managing product information like descriptions, specifications, and attributes. Their DAM features usually cover only simple image storage and basic metadata. They cannot handle complex workflows or large media libraries efficiently.

A high-end DAM system offers much more: advanced workflow automation for multi-department approvals, built-in image editing, automatic format conversion, and AI-powered auto-tagging and smart search to find any asset in seconds.

The combination of PIM and DAM is the real game-changer. PIM manages product data, while DAM organises and distributes all related assets. Together, they synchronise in real time for maximum efficiency.

Success with CELUM: The Kistler story

The company

The Kistler Group is a global leader in dynamic pressure, force, torque, and acceleration measurement technology. With 2,200 employees across 60 locations and a turnover of 465 million CHF (2022), Kistler develops innovative high-tech sensors for the automotive industry, industrial automation, and more.

The challenge

Kistler recognised the growing importance of online sales and aimed to build a modern B2B e-commerce channel for its high-tech products. But it faced significant technical hurdles:

- Outdated IT infrastructure, with legacy CMS tools no longer fit for purpose

- Lack of integration, as ERP and CRM systems worked in silos

- Inefficient content management due to an outdated, partially integrated DAM

- Decentralised product content, with marketing materials and technical documents scattered across systems

The solution: CELUM’s DAM for manufacturing

Kistler implemented a comprehensive digitalisation strategy with two key pillars:

- SAP Commerce Cloud as the central CMS and e-commerce platform for seamless online ordering and catalogue management.

- Migration to CELUM Product Content Management (PCM), upgrading from an on-premise DAM to a cloud-based DAM focused on Product Content Management, seamlessly integrated with SAP Commerce Cloud.

The results and benefits

Kistler’s transformation brought remarkable improvements:

Central content management: all product content, from marketing materials to CAD files, is now stored and managed centrally in CELUM, eliminating redundancies.

Optimised workflows: teams collaborate more efficiently with CELUM’s intuitive interface and secure access management.

Automated website updates: integration between CELUM PCM and SAP Commerce Cloud enables one-click content updates and automatic SEO text synchronisation in seven languages.

Increased efficiency: marketing and sales teams now use assets more effectively across all channels, with automated distribution to the right audience at the right time.

The importance of DAM in manufacturing in a nutshell

Digital Asset Management has become indispensable for modern manufacturing. The growing time-to-market pressure, complex data, and multi-channel requirements can only be managed with a professional DAM solution.

A well-implemented DAM system speeds up product launches, improves team collaboration, and ensures brand consistency. At the same time, it cuts costs and reduces risk through better compliance and security.

In manufacturing, investing in a DAM system pays off quickly. You save time, reduce errors, and can focus on what truly matters: developing innovative products for your customers.